Combating climate stress with well thought-out space solutions

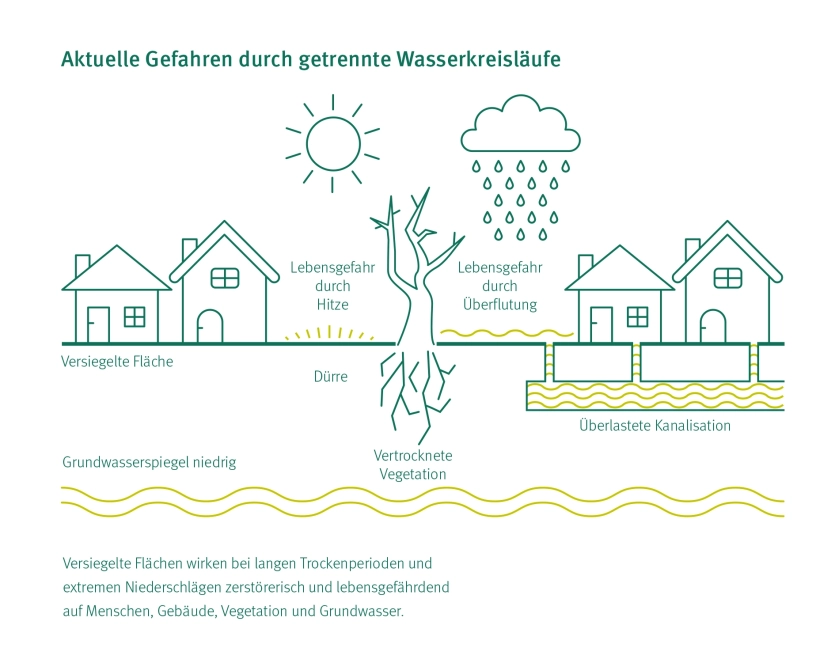

The concept of the sponge city is more relevant than ever. In view of increasing dry periods, intense heavy rainfall events and local flooding, a climate-resilient transformation of our cities is overdue.

While measures such as green roofs, green facades, retention roofs and reservoirs as well as rainwater harvesting and infiltration systems are already established, one area holds enormous potential: the unsealing of traffic areas.

These account for up to 17% of the total area of our cities - in inner-city areas even up to 40%. Currently, rainwater from these areas is usually channeled directly into overloaded combined or rainwater drains. This not only leads to flooding, but also removes valuable water from the city.

The consequences:

Every day, over 50 hectares of land are built on in Germany - around half of which is completely sealed. Any further sealing exacerbates the existing challenges.

The solution: proactive surface concepts.

With water-permeable paving solutions and climate-active coverings, such as the GDM.climate stone, we offer building blocks for the sponge city of the future - ecological, functional and sustainable.

Because climate adaptation begins on solid ground.

The increasing sealing of streets, squares and areas means that precipitation cannot seep away where it falls. During extreme rainfall, the sewer networks are completely overloaded. The result is devastating flooding with catastrophic consequences.

Rain must seep away on site so that cities can protect themselves against heavy rainfall events.

For over 40 years, we have been developing paving systems that go far beyond traditional applications. Our claim: surface coverings that actively contribute to climate adaptation - ecologically, functionally and in terms of design.

Whether green, permeable, cement-reduced or climate-active - our solutions are the result of decades of research and a passion for sustainable construction.

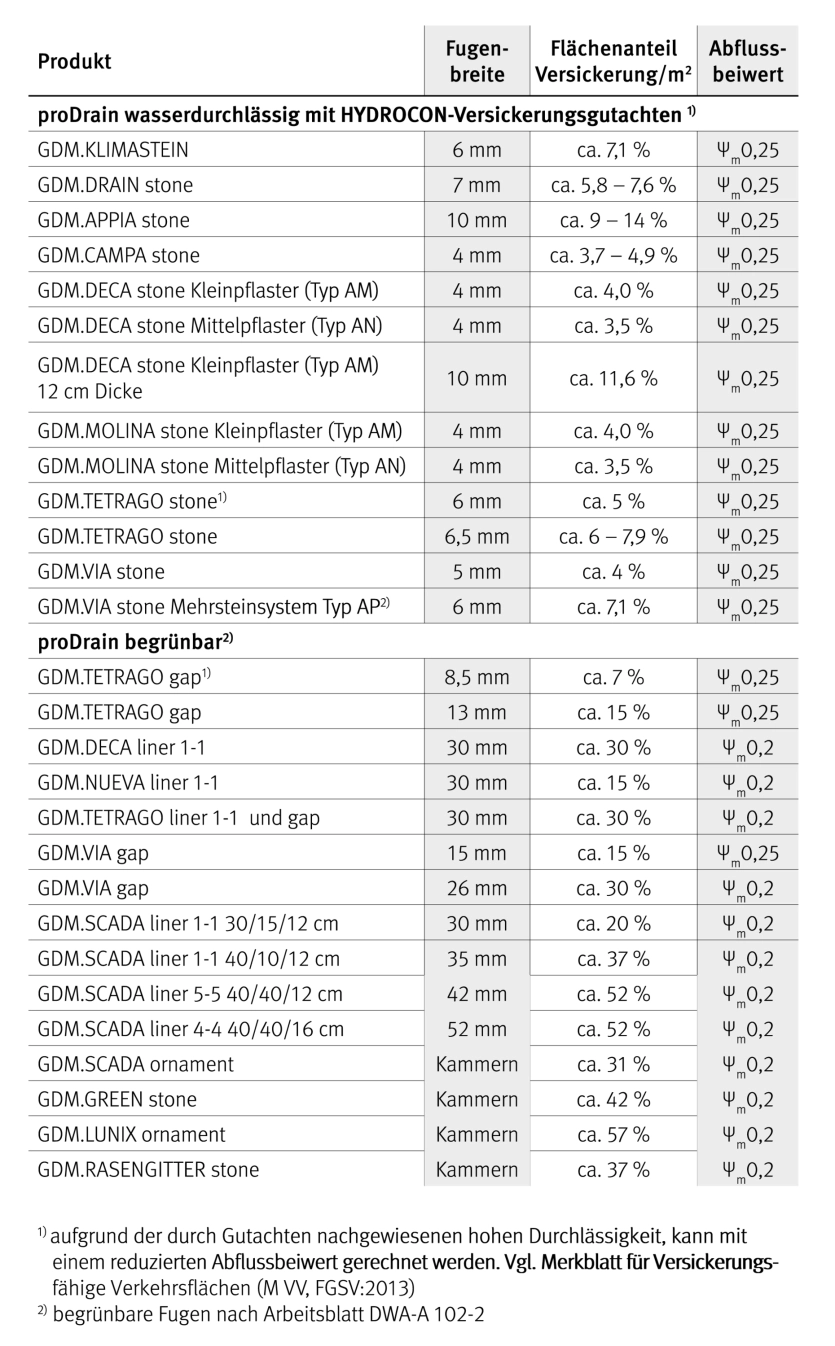

The runoff coefficient is a decisive parameter in the planning and dimensioning of drainage facilities and infiltration systems on properties. It is used to determine the resulting runoff based on a design rainfall and enables the correct dimensioning of the systems to be installed. In addition, the runoff coefficient allows conclusions to be drawn about the amount of precipitation that does not run off an area. This information is particularly relevant for properties that are connected to existing drainage facilities in order to quantitatively determine the proportion of precipitation that is not discharged into the drainage facilities. This calculation can serve as the basis for any reductions in the rainwater charge .

The determination of runoff coefficients for paved traffic areas often varies between cities and municipalities and is not always based on current technical regulations or scientific findings. The SLG concrete association has therefore systematically researched the current status of technical regulations (e.g. DIN 1986-100) and scientific studies (e.g. Illgen 2009) in order to provide up-to-date and practical average values for runoff coefficients.

A detailed differentiation of runoff coefficients for different traffic areas would be possible in principle, but not necessary or expedient. The variability of the influencing factors, such as duration and intensity of precipitation, surface quality, slope of the traffic area, duration of the precipitation and the colmation (soiling) of the seepage joints and openings, makes a generally valid application complex. For the design of new drainage facilities, it is therefore essential to follow the relevant standards, such as DIN 1986-100, in order to ensure that the design meets the technical requirements.

The runoff coefficient indicates what proportion of the precipitation on an area is discharged, based on the design rainfall rate (270 l/(s x ha) for a 10-minute rainfall event with a 5-year frequency). The lower the value, the lower the surface runoff and the greater the infiltration rate. In addition to the selected paving stone or slab, the size of the runoff coefficient is primarily dependent on the local conditions. In particular, these are the infiltration capacity of the building materials used for the base course, bedding and joints, the permeability of the subsoil, any soiling and the slope of the surface as well as the local precipitation conditions. In the case of grass joint paving, the joint substrate used also plays a decisive role. For this reason, the "average runoff coefficients" given can only represent an average. The actual values for each individual surface may vary upwards or downwards.

Expert reports confirm that our products exceed the prescribed infiltration capacity of 270l/(sxha).

Green paving systems create a design transition between paved surfaces and adjacent green areas. Their purpose is not only to infiltrate rainwater, but also to delay surface runoff. In this way, they help to relieve the drainage infrastructure.

They also contribute to the microclimate: moisture absorbed by the plant roots is released into the environment through evaporation. However, this requires a sufficient water supply. During prolonged dry periods, irrigation is necessary to maintain the vegetation.

In terms of accessibility, green paving systems have limitations and are unsuitable for people with limited mobility without supplementary measures. In such cases, a combination with conventional coverings within the movement areas is necessary

Drainage joint blocks are joint-tight paving blocks manufactured in accordance with DIN EN 1338 and specially developed for the targeted drainage of rainwater on traffic areas. Drainage takes place via technically designed joint spaces through which the water infiltrates into the superstructure. This supports the natural water cycle and relieves the burden on the public drainage infrastructure.

Functional drainage joint blocks are characterized by a balanced relationship between surface area and joint width. As a result, they can be used to create

low-vibration paving surfaces that still meet the requirements for barrier-free paving.

Stones with a dense structure offer a high mechanical load-bearing capacity and also exhibit above-average resistance to freeze-thaw cycles. Their surface can be individually designed or finished to resemble factory-made stone using a wide range of facing formulations.

Water purification through joint material

Modern systems use a specially developed joint material that filters dirt, dust and pollutants out of the run-off water. This construction method has been tested by the German Institute for Building Technology (DIBt) and has a general type approval (aBG). The paving thus also acts as a treatment system for rainwater ( proWater system).

The paved surface retains pollutants and fine particles close to the surface without permanently impairing water permeability. To maintain functionality, regular cleaning using a rinsing and suction process is required (every 10-15 years). The joints are emptied to a depth of 2-3 cm and then completely refilled. In this way, around 90 % of the original infiltration capacity can be restored, which means that an average runoff coefficient of 0.0 can be applied.

Climatic effect

As drainage joint stones store little moisture in the joint space, their contribution to evaporative cooling in the microclimate is small. Their primary benefit lies in the controlled drainage and, if necessary, cleaning of rainwater.

Paving stones with porous aggregates, also known as water-permeable or porous paving stones, are increasingly being used in road construction - especially where rainwater should seep away as directly as possible on site.

Their structure contains numerous cavities that allow rainwater to pass through the stone and the joint into the substructure and further into the ground. This has both ecological and economic benefits, but requires careful planning.

Regenerability through cleaning

Over time, the pores of the paving and base layer can become clogged with dirt particles (colmation), which reduces the infiltration capacity.

Regular cleaning - usually every 10 to 15 years - using a rinsing and suction process largely restores the original permeability and filter function.

Paving with aggregate spores is particularly suitable for areas with low to medium traffic loads, such as footpaths, parking areas or traffic-calmed zones. Careful structural design is required in areas subject to heavier traffic. In addition, the structure must be planned to be frost-proof in order to avoid damage caused by water and ice.

Paving blocks with porous aggregates represent a sustainable alternative to conventional pavements in the context of climate-adapted and resource-conserving infrastructure construction. However, their effectiveness is largely dependent on professional planning, dimensioned construction principles and regular maintenance measures. When used properly, they make a valuable contribution to the ecological and water management qualification of urban spaces.

Innovative paving system for climate-active urban areas

The GDM.KLIMASTEIN is a pioneering development in the field of water-permeable traffic areas. As the world's first paving block with a three-layer structure, it combines the advantages of porous and impermeable paving systems in a functional hybrid concept. The block consists of a structure-tight facing layer, a storage layer with porous structure and a base layer with capillary pores. It fulfills all structural and ecological requirements in an unprecedented way.

When it rains, water is absorbed via the joints and the porous facing layer. The water is then temporarily stored in the storage layer where it is available for evaporation. Measurements show that with a stone thickness of 8 cm, up to 10 liters per square meter can be retained.

The capillary base layer prevents direct release of the stored moisture to the bedding, but at the same time allows moisture to be returned from the bedding to the storage layer. As a result, the evaporation rate can be increased to over 50% of the annual rainfall - a value that corresponds to the natural evaporation behavior of meadow areas. This dual effectiveness - infiltration and re-evaporation - makes the GDM.KLIMASTEIN a key building block for climate-resilient urban development based on the sponge city principle.

Despite the integration of porous structures, the GDM.KLIMASTEIN fully complies with the requirements of DIN EN 1338 for joint-tight concrete paving blocks. This makes the system suitable for traffic areas up to load class Bk1.8 - a level that corresponds to around six times the typical application limit of classic porous paving systems (Bk0.3). This considerably extends the range of applications, especially for:

The increasing number of local authorities converting to 30 km/h zones in urban areas creates additional planning scope for the use of this innovative surface.

In combination with a special joint material tested in accordance with the general construction type approval (aBG), the GDM.KLIMASTEIN also performs a filter function: pollutants such as heavy metals, hydrocarbons or microplastics are retained as soon as they pass through the joints. This eliminates the need for separate rainwater treatment systems in many applications.

The GDM.KLIMASTEIN is more than just a paving stone - it is an active element in the system of climate-adapted urban development. Thanks to the combination of mechanical load-bearing capacity, hydraulic performance and climatic impact potential, it offers a technologically and ecologically superior solution for modern traffic areas that meets the requirements of climate change and resource conservation.

Innovative. Climate active. Fit for the future.

The GDM.KLIMASTEIN is more than just a paving block - it is an integral building element for the climate-adapted city of the future. As a heavy-duty paving system, it combines technical performance with ecological added value and offers a holistic solution to the challenges of urban climate change.

With this triad of functions, it makes a significant contribution to reducing heat islands, improving the water balance and protecting soils and water bodies. At the same time, it meets the requirements of modern traffic areas in terms of load-bearing capacity and durability.

GDM.KLIMASTEIN makes surfaces climate-resilient - and cities sustainable.

proDrain

Decentralized surface infiltration supports the preservation of the natural water balance on site and relieves the sewer network.

proVapo

Evaporation activity improves the urban climate: higher humidity and more cooling.

proWater

The joint material filters pollutants out of rainwater from traffic areas: Groundwater protection.

proAir

Thanks to a modified concrete formula, the surface contributes to the reduction of air pollutants

proReflect

The surface reflects heat from solar radiation and protects against overheating.

proSilence

Certain formats, the joint width and surface structure, as well as the laying pattern guarantee a particularly quiet paving surface.

proCycle

Conserves raw material resources through recycling and upcycling.

proPower

Intelligently arranged spacers on the brick flanks create a positive and non-positive bond.

Building sustainably - with a good feeling.

All GODELMANN products are Cradle to Cradle Certified® Gold - one of the strictest sustainability seals in the world. For you this means

Good for today. Right for tomorrow.

With GODELMANN, you are opting for durable products – and for genuine environmental protection that has been thought through.